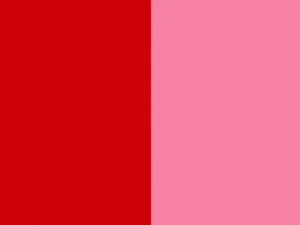

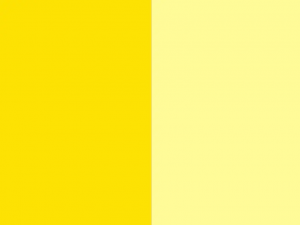

Hermcol® Yellow HG (Pigment Yellow 180)

Features

Hermcol® Yellow HG is a semi-opaque medium shade benzimidazolone pigment yellow 180 with high color strength, excellent fastness properties and high heat-fast requirements. It is a grade with an extreme low foaming behavior that especially is designed for decorative inks. Hermcol® Yellow HG is becoming increasingly important and is utilized in printing inks to suit particular applications where diarylide yellow pigments cannot be used. A special grade is also commercially available which is recommended for the coloration of solvent and water based packaging gravure and flexo printing inks.

Application

Recommended for solvent and water based packaging gravure and flexo printing inks. Suggested for paint and UV ink, water based inks.

Package

25kgs or 20kgs per paper bag/drum/carton.

*Customized packaging available on request.

QC and Certification

1. Our R&D laboratory features equipment such as Mini Reactors with Stirrers, Pilot Reverse Osmosis System and Drying Units, making our technique in the lead. We have standard QC system which meets EU standard and requirements.

2. With the quality management system certificate of ISO9001 and environmental management system certificate of ISO14001, our company not only sticks to the strict quality-control system according to the international standard, but also focuses on protecting the environment and promoting the sustainable development of itself and the society.

3. Our products meet the stringent mandatory requirements of REACH, FDA, EU's AP(89)1 &/or EN71 Part III.

Details

|

General Properties |

||||||||||||

|

Properties |

Solvent Resistance&Plasticizer |

Chemical Properties |

||||||||||

|

Density |

Oil Absorption |

Specfic Surface Area |

Water Resistance |

MEK Resistance |

Ethyl Acetate Resistance |

Butanol Resistance |

Acid Resistance |

Alkali Resistance |

||||

|

1.42 |

40±5 |

24 |

5 |

5 |

5 |

5 |

5 |

5 |

||||

| Application | ||||||||||||

|

Coating |

||||||||||||

|

Light Resistance |

Weather Resistance |

Re-coating Resistance |

Heat Resistance℃ |

Car Coating |

|

Powder Coating |

Architectural Decoration Coating |

|||||

|

Full Shade |

1:9 Reduction |

Full Shade |

1:9 Reduction |

|

|

|

Water-based Coating |

Solvent-based Coating |

PU Coating |

Epoxy Coating |

|

|

|

7-8 |

6-7 |

5 |

4-5 |

5 |

200 |

|

|

+ |

|

|

+ |

|

|

Plastic(Color Master Batch) |

||||||||||||

|

DIDP Resistance |

Properties |

Light Resistance |

Heat Resistance |

|||||||||

|

|

Oil Absorption |

Migration Resistance |

Full Shade |

Reduction |

LDPE System |

HDPE System |

PP System |

ABS System |

PA6 System |

|||

|

|

|

5 |

7-8 |

6-7 |

290 |

290 |

290 |

290 |

290 |

|||

|

Ink |

||||||||||||

|

Gloss |

Hiding Power |

Physical properties |

Application |

|||||||||

|

|

|

Light Resistance |

Heat Resistance |

Steam Resistance |

NC Ink |

PA Ink |

Water Ink |

Offset Ink |

Screen Ink |

UV Ink |

PVC Ink |

|

|

|

|

5 |

5 |

|

+ |

|

+ |

|

|

|

|

|